Hwashin Bolt Industries actively responds to the changing needs of customers, and is constantly conducting R & D on special materials and special shape bolts.

R&D Center Research Institute

Analysis

Material Research and Analysis

Development

R & D of precise material processability

Perform

Government R & D Research Projects

Link Project

Hwashin Bolt Industries is engaged in field application technology development, creative talent training and joint research through industry-academia cooperation projects.

BUSAN INSTITUTE OF SCIENCE AND TECHNOLOGY

KOREA MARITIME AND OCEAN UNIVERSITY

BUSAN AUTOMOTIVE HIGH SCHOOL

BUSAN TECHNICAL HIGH SCHOOL

R&D Project

– Hwashin Bolt Industries is carrying out research and development projects aiming to develop new products

and improve productivity in order to meet various customers and environment changes.

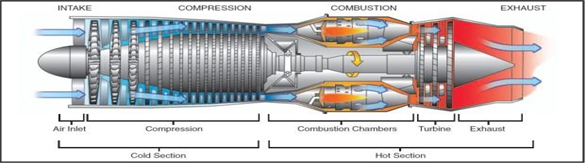

– Developed Product : Compressor Rotor Bolt.

- A component that penetrates and fixes a high-temperature, high-speed rotating compressor disk.

- The highest value of the highest value added turbine components.

- Stability and quality are very important, and customer’s quality requirements are very strict.

- Precision machining technology for hard metal, long axis concentricity

/ straightness securing technology, surface treatment technology, Complex technology such as quality inspection technology is required.

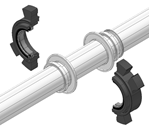

Split Mechanical Seal

Existing Mechanical Seal

- Assemble the perturbation part on the rotating shaft in the axial direction

- Disassemble the entire rotating device when replacing after a certain period of use.

- Increase maintenance time / cost

Separate Mechanical Seal

- Pivoting parts on the rotating shaft are assembled from both sides

- Easily disassembled and assembled when replacing (Maintenance time, cost reduction)

Excellence and differentiation of development technology

No need to disassemble the entire pump for mechanical seal replacement.

Replacement time: 10 ~ 12 hours -> 1 hour

More than 90% cost savings